No products in the cart.

Process

Foil stamp process introduction|hot foil stamping|gold foil business cards

What is hot foil stamping?

Hot stamping (also known as foil stamping) originated in the 19th century, when Ernst Oeser recorded the first hot stamping patent in Germany in 1892. After more than 100 years of development, hot stamping is more and more widely used in our printing process. Since 1970, it has become one of the most important decoration methods for printed surfaces.

How does hot foil stamping work?

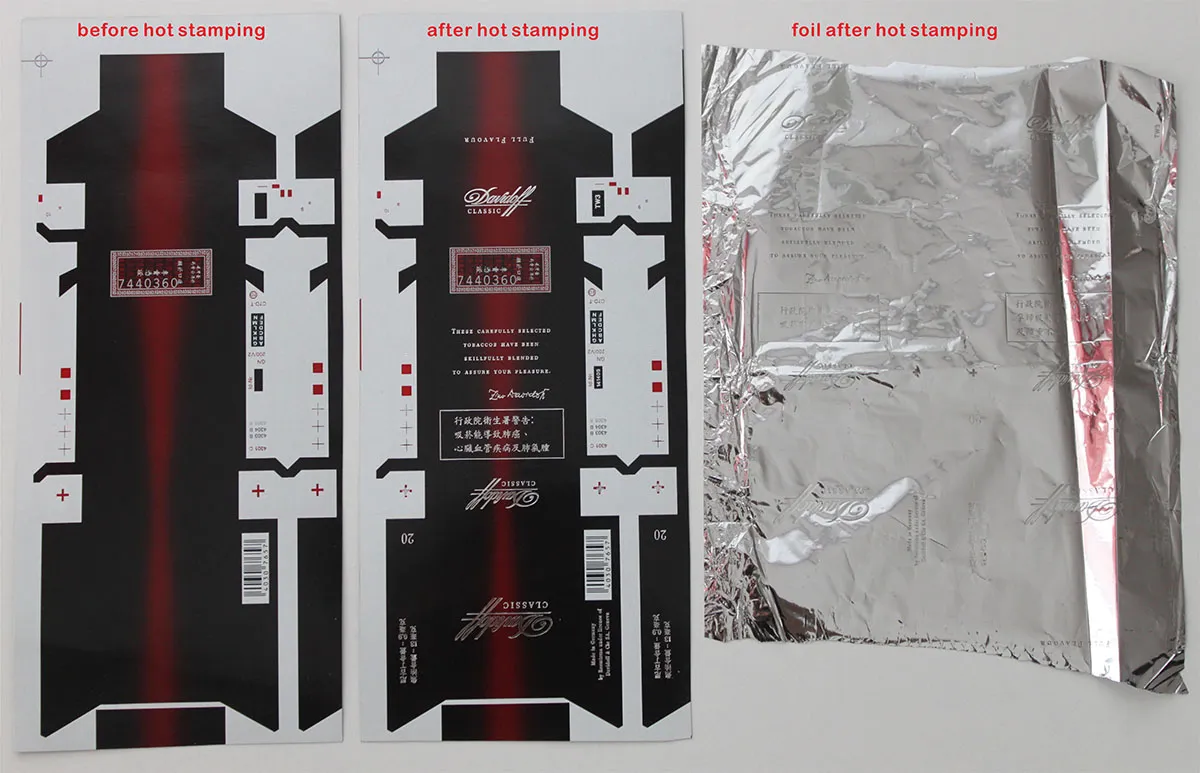

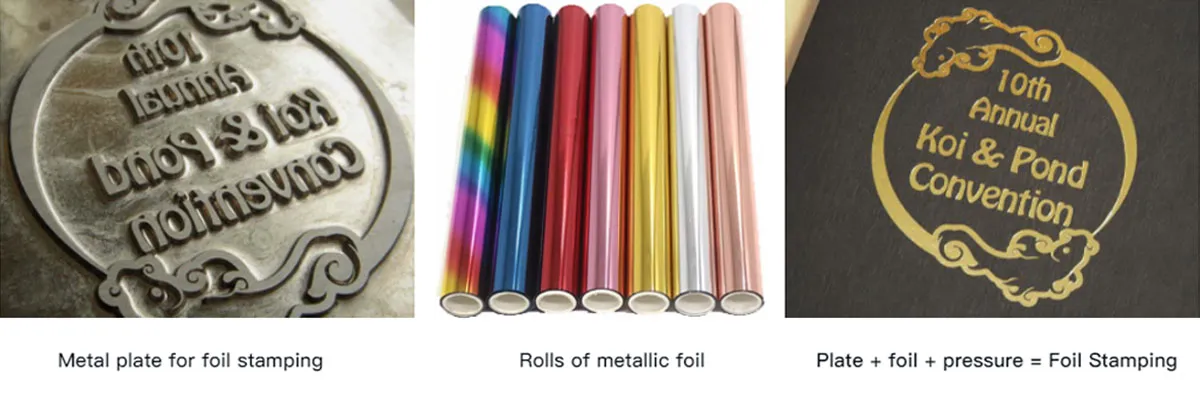

Hot stamping is a special printing process without ink.In a hot stamping machine, a die is mounted and heated, with the product to be stamped placed beneath it. A metallized or painted roll-leaf carrier is inserted between the two, and the die presses down through it. The dry paint or foil used is impressed into the surface of the product. The dye-stamping process itself is non-polluting because the materials involved are dry.Pressure and heat cause the relevant sections of the foil to become detached from the carrier material and become bonded with the printing surface.

What tools do hot foil stamping need?

Along with foil stamping machines, among the commonly used tools in hot stamping are dies and foil. Dies may be made of metal or silicone rubber, and they may be shaped directly or cast. They can carry high levels of detail to be transferred to the surface and may be shaped to accommodate irregularities in the surface.

Foils are multilayered coatings that transfer to the surface of the product. Non-metallic foils consist of an adherence base, a color layer, and a release layer. Metallic foils replace the color layer with a layer of chrome or vacuum-metallized aluminum. Metallic foil construction has a metal-like sheen and is available in different metal shades such as gold, silver, bronze, and copper. Pigment foil does not have a metallic sheen but may be glossy or matte. Holographic foil paper includes a three-dimensional image to provide a distinctive appearance to specific areas of a digitally printed application. Printing is often done on leather or paper.

Different hot stamping machines serve different purposes, but the most common hot stamping machines are simple up-and-down presses. Three of the most common brands are Kwikprint, Kingsley, and Howard. However, for more industrial applications, Kluge and Heidelberg presses are more commonly used.

What are the advantages of hot foil stamping?

Compared to other printing methods, hot stamping has several advantages, including the following:

- It can be used to print over a wide range of materials, including leather, rubber, paper, plastic or fabric.

- As a printing method, it can be customized to fit the needs of the customer (e.g. in terms of quantity or printing depth).

- It’s quite a simple printing process which does not require complex machinery or highly expensive consumables.

- It does not require the use of ink, making it a cleaner process compared to other printing methods.

- It will make the printed matter more high-grade and exquisite, magnificent and full of individuality.

What can hot foil stamping be used for?

- If you’re looking to personalize your product by adding your name, monogram, or company logo, hot stamping is a tried and true direct part marking method.

What file format is needed for hot foil stamping?

- A great looking foil imprint starts with a crisp, clean, black and white image. Your artwork can be a graphic, a logo, typographic lettering, just text, or a combination of these elements. Artwork should not contain fine lines, gradients, drop shadows, or textures as these will not produce a desirable result.

- The minimum line shall be greater than 0.15mm. If it is too thin, it will not appear on the plate.

- Most popular file formats: PDF, AI, EPS, CDR