No products in the cart.

未分类

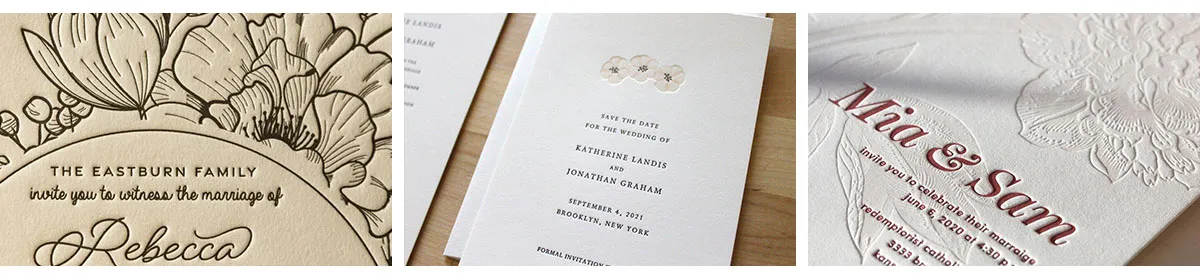

letterpress introduction|letterpress business cards

What is letterpress?

The letterpress is the oldest form of printing whereby letters were arranged on a frame, dipped in ink and then pressed onto the printing substrate to produce an impression. Letters were carved on the surface of wood, metal or stone to use on the printing press. The letterpress was used by hand, and this method was later replaced by typewriters and then modern-day printers.

The letterpress was the predominant method of document printing since the mid-15th century, when movable type was invented by Johannes Gutenberg. The printing industry was revolutionized by the invention of rotary press, after which books and other printed medium such as newspapers were made in bulk. Xerox machines and printers have greatly simplified the task of printing, and hundreds of copies can be made in minutes, whereas when using a letterpress, making a single copy required an enormous amount of effort.

The letterpress is currently having a renaissance of sorts by modern-day enthusiasts who prefer classic printing processes over modern methods.

How are modern letterpress plates made?

The original movable types that Gutenberg and his contemporaries used were engraved wood or metal plates. Although modern letterpress printing is very similar to Gutenberg’s, polymer or photopolymer plates are used instead. Polymer plates, categorized as “flexible relief plates,” allow people to make letterpress prints out of designs from a computer. Digital designs have certain constraints, such as having lines that can’t be too thin. Additionally, since letterpress printing can only be done in one color at a time, separate designs must be created for each color if multiple colors are desired on the finished product.

Once a digital design is finished on the computer, it is printed as a film negative. This film negative must be put on top of a polymer plate and then exposed to ultraviolet light, similar to the photographic exposure process. Because polymer plates are light-sensitive, the parts exposed to light through the cutouts of the film negative will harden. When this is finished, the polymer plate must be rinsed with water and the unexposed areas will be washed away. The hardened part is known as the “relief.” This is the part that will be covered with ink for letterpress printing. These flexible relief printing plates have also been used outside of letterpress printing, such as for jewelry making or leatherwork.

Why is Letterpress printing so expensive?

- Letterpress is very labour-intensive processes for the printer

- Each sheet has to be manually hand-fed into the press

- You need to use specialist papers that will show off the impression left by the press

- The plates too, are not cheap or easy to create and require specialist equipment to make

- If you require a multiple colour design, you will need a plate for each colour (which is why it is so much more expensive compared to single colour designs)

- You need specialist materials and skills to maintain vintage machinery

Letterpress printing isn’t your usual “press print and go” process – there’s no USB ports on these old machines for starters! But this is also what makes it so special, and brings that wonderful “old world” feel to your invitations.

What products are available with Letterpress?

We have a wide range of products available with Letterpress output. The most popular uses for Letterpress include:

- Business Cards

- Wedding Invitations

- Posters