No products in the cart.

What is Laser Cut?

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, Now it is used by more and more enthusiasts for business card printing. The laser optics and CNC (computer numerical control) are used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

How does Laser cutting work?

Laser beam is generally focused using a high-quality lens on the work zone. The quality of the beam has a direct impact on the focused spot size. The narrowest part of the focused beam is generally less than 0.0125 inches (0.32 mm) in diameter. Depending upon material thickness, kerf widths as small as 0.004 inches (0.10 mm) are possible. In order to be able to start cutting from somewhere other than the edge, a pierce is done before every cut. Piercing usually involves a high-power pulsed laser beam which slowly makes a hole in the material, taking around 5–15 seconds for 0.5-inch-thick (13 mm) stainless steel, for example.

The parallel rays of coherent light from the laser source often fall in the range between 0.06–0.08 inches (1.5–2.0 mm) in diameter. This beam is normally focused and intensified by a lens or a mirror to a very small spot of about 0.001 inches (0.025 mm) to create a very intense laser beam. In order to achieve the smoothest possible finish during contour cutting, the direction of beam polarization must be rotated as it goes around the periphery of a contoured workpiece. For sheet metal cutting, the focal length is usually 1.5–3 inches (38–76 mm).

Advantages of laser cutting over mechanical cutting include easier workholding and reduced contamination of workpiece (since there is no cutting edge which can become contaminated by the material or contaminate the material). Precision may be better, since the laser beam does not wear during the process. There is also a reduced chance of warping the material that is being cut, as laser systems have a small heat-affected zone.Some materials are also very difficult or impossible to cut by more traditional means.

Laser cutting for metals has the advantages over plasma cutting of being more precise and using less energy when cutting sheet metal; however, most industrial lasers cannot cut through the greater metal thickness that plasma can. Newer laser machines operating at higher power (6000 watts, as contrasted with early laser cutting machines’ 1500 watt ratings) are approaching plasma machines in their ability to cut through thick materials, but the capital cost of such machines is much higher than that of plasma cutting machines capable of cutting thick materials like steel plate.

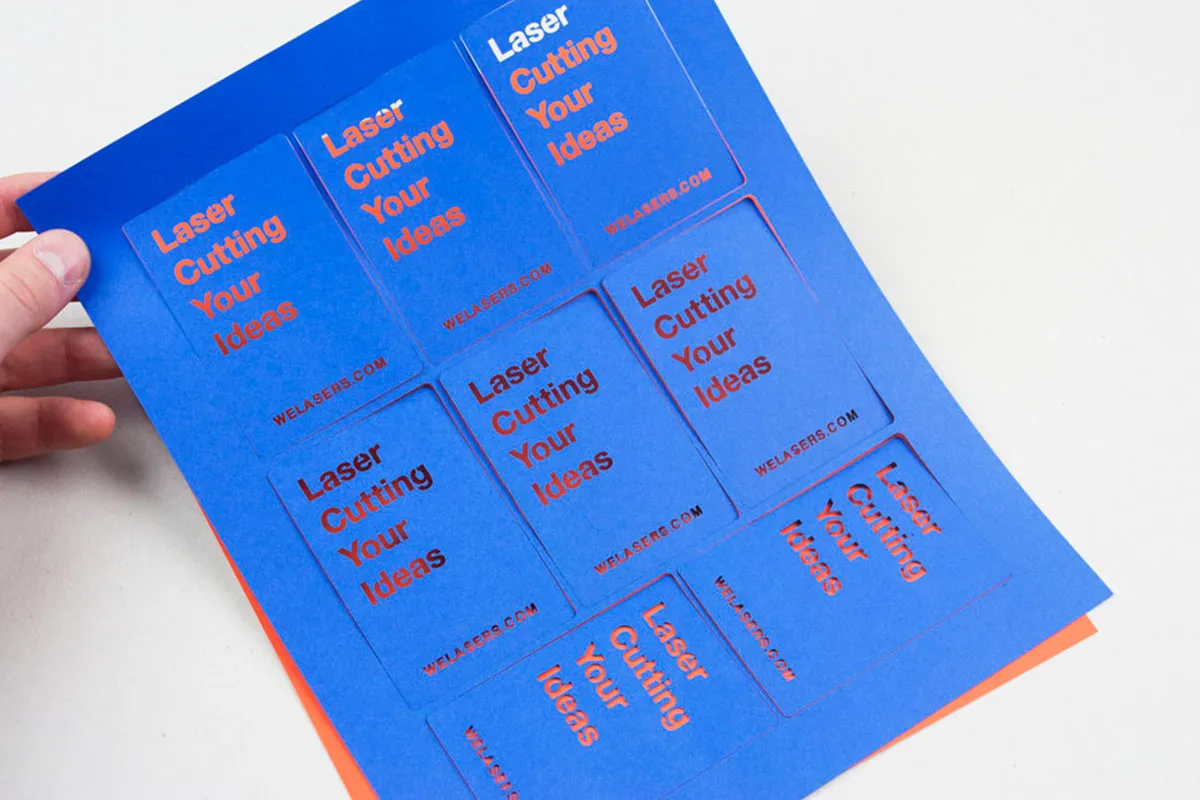

Application of laser cutting in business card

OK, farewell to the boring teaching, let’s take a look at the application of laser cutting in real business cards:Business cards serve as an important link in interpersonal communication.It is not only a symbol of status, but also an important tool for people to socialize.Unique business card design can enhance corporate image.Get a good impression from the customer.Laser cutting business cards give creative ideas to business.

Combine the company’s corporate culture with business card design.Using laser cutting to show the brand value of business cards.And with unique design, in the first time to leave a deep impression.Make common business cards more recognizable.Make it stand out from other business cards

Business cards of different materials can make laser engraving machines show their talents.Even without fancy colors.Return to original simplicity visual embodiment and modern laser hollowing technology.So that the aesthetic extends from the visual to the tactile.It is also the continuation of the user’s personality charm.

Business cards, like people, have personality and have life.Laser engraving machine remodeling business card design.Give the business card a new look and a higher social value.Use a laser hollowed out business card.Enhance enterprise brand image, display unique identity.